Bygen’s Patented Low Temperature

Activation (LTA) Technology

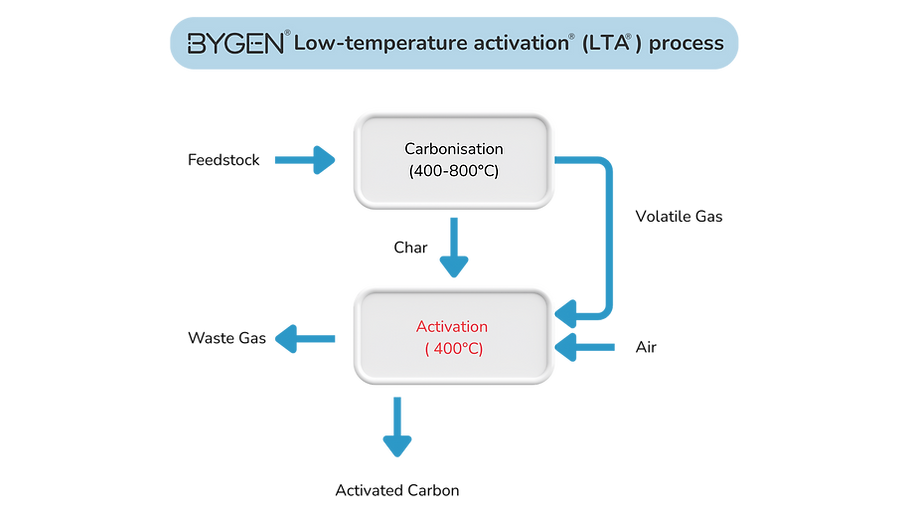

Bygen has developed the world’s first Low Temperature Activation (LTA) process - a revolutionary way to produce high-performance activated carbon from sustainable feedstocks with dramatically lower energy requirements and emissions.

For decades, the industry has relied on energetically expensive, high-temperature processes. Bygen’s LTA technology changes this entirely - delivering premium-quality activated carbon through a process that is smarter, cleaner, and more sustainable.

How LTA Works - The Bygen Difference

Our patented LTA process combines carbonisation and activation into a single, integrated system. Instead of relying on costly activation with steam or CO₂, LTA uses air and recycled off-gases from the initial carbonisation stage to activate at much lower temperatures than traditional methods.

Unlike other activation methods, the reaction at the core of LTA is exothermic - it produces its own heat, making the process largely self-sustaining and generating significant excess heat compared to conventional activation.

%20process_transparent%20bg.png)

Why LTA Changes the Game:

-

World-first innovation: patented technology unique to Bygen

-

Ultra energy-efficient: reduced reliance on external fuel and high-temperature steam

-

Sustainable from the ground up: uses sustainably sourced biomass feedstocks; currently validated for soft biomasses such as almond shell and wood chips, with ongoing R&D to expand applicability to other feedstocks

-

Closed-loop gas recycling: minimises emissions and environmental impact

-

Consistent high quality: pore development optimised for superior adsorption

-

Performance stability: maintains adsorption efficiency over long deployment periods

-

Scalable and reliable supply: suitable for utilities, councils, and large-scale industrial operations

Environmental & ESG Advantages:

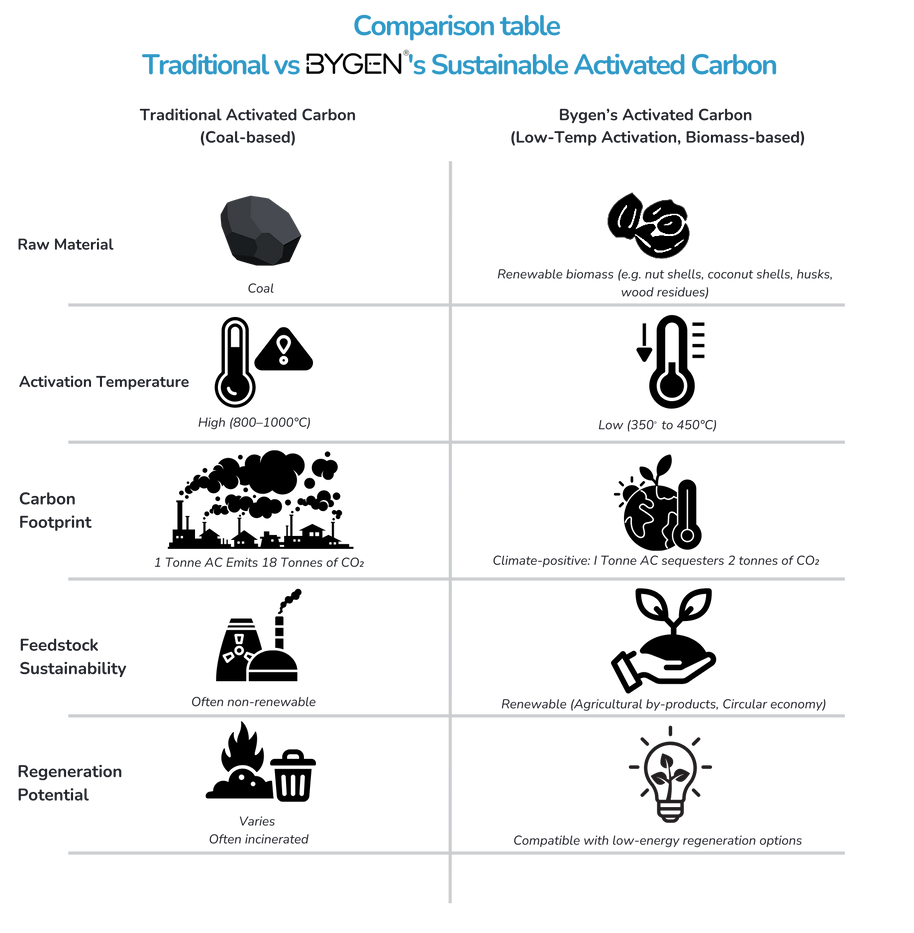

At a production plant under construction in North America, Bygen’s LTA technology has recently been independently validated via a Lifecycle Analysis (LCA) as being carbon-negative, in accordance with ISO 14040, 14044, and 14067 standards. Great news for our process and confirmation of our expectations.

-

Base LCA result: 0.37 kg CO₂/kg AC produced

-

Coconut shell AC (India): ~1.9 kg CO₂/kg AC

-

Coal AC (China): ~11.1 kg CO₂/kg AC

-

When factoring in carbon sequestration from Bygen’s process: –3.0 kg CO₂/kg AC net reduction

Lower greenhouse gas emissions through reduced fossil fuel use

-

Significant energy savings from low-temperature activation

-

Reduced transport footprint via integrated production and being closer to customers

-

Sustainable feedstocks sourced from renewable biomass

These benefits help our customers meet ESG targets and align with sustainable procurement frameworks.

Additional ESG benefits:

Performance Consistency

Testing to date indicates that Bygen’s LTA activated carbon performs on par with leading incumbent carbons across multiple applications, providing confidence that adopting LTA maintains treatment efficacy while delivering the sustainability benefits of our process. We continue to refine our LTA process to optimise for new feedstocks and projects, using our in-house pilot production facilities to trial, validate, and enhance performance before full-scale implementation.

Benefits by Application

Bygen’s LTA-activated carbon delivers high performance across:

Explore our case studies: See how LTA is delivering measurable performance, reliability, and sustainability benefits for our clients. View case studies.

Comparison: Traditional vs Bygen's Sustainable Activated Carbon

.png)

Setting a New Global Standard

With LTA, Bygen is proving that advanced performance and sustainability can go hand in hand. Our technology is:

-

Changing the economics of activated carbon production

-

Unlocking new opportunities for industries that demand high-quality adsorbents

-

Leading the way to a lower-carbon future in environmental treatment technologies

Whether for water purification, air filtration, gold recovery, or PFAS removal, Bygen’s LTA delivers exceptional adsorption performance while reducing environmental impact.

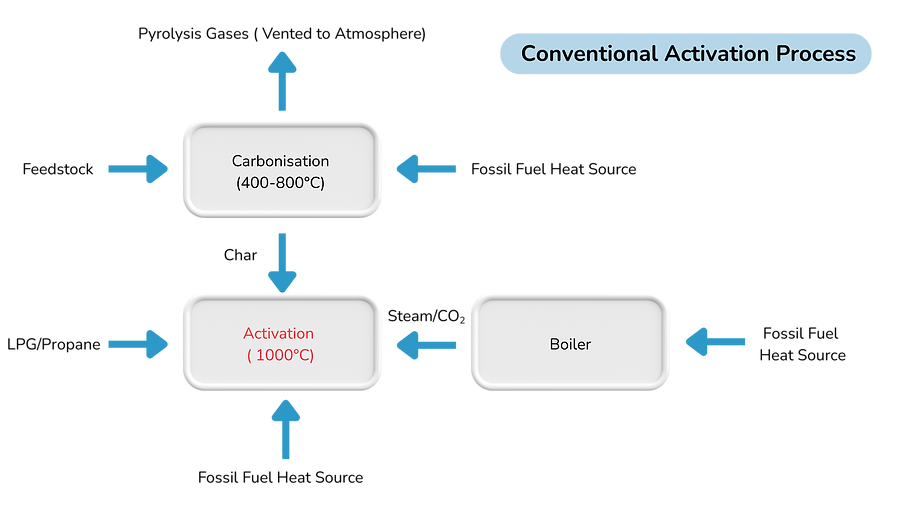

The Limitations of Conventional Activation

Traditional activation methods often rely on high-temperature steam or CO₂, making them energy-intensive, slow, and costly. These processes:

-

Require substantial external heat (for activation and steam generation)

-

Can take up to eight hours and require expensive reagents in the case of CO₂ activation

-

Are frequently split across multiple facilities, losing valuable heat between stages

-

Often release harmful off-gases without proper combustion

The result: high costs, high emissions, and low efficiency.

Complete the form below to contact Bygen and discover how our world-first LTA technology can transform your supply chain and sustainability goals.

CONTACT US

10 Platinum St,

Thomastown, VIC 3074

Phone: +61 3 9465 2140

General Enquiries: info@bygen.com.au

Sales Enquiries: sales@bygen.com.au